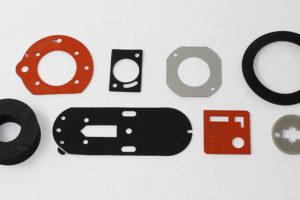

From simple ID/OD washers to more complex two-dimensional shapes, and parts that are kiss-cut or relief-cut, RMI is committed to supplying our OEM customers with competitive pricing and prompt turnaround for their custom cut gasketing requirements.

RubberMill’s staff can help you identify a gasketing material or quote to your print specification. Most gasket materials are available with or without pressure sensitive adhesive (PSA) that has a peel-off liner.The dieless cutting method allows RubberMill to provide quick turn around on mock-ups or samples for approval before customers invest in steel rule or rotary dies for production quantities.

If it is a existing part and you need production parts quickly, RubberMill’s in-house die-making team can respond quickly and ship samples for approval within days of order receipt when necessary.

If you are designing a gasket, please visit the technical data section of this web page under Manufacturing Tolerances of Rubber Parts for die cut tolerance guidance. Most gasket material will fall under either the dense rubber or sponge rubber tolerance guidelines.

RubberMill quotes all gasket requirements to Rubber Manufacturers Association Commercial tolerances.