Selecting the Most Cost-Effective Material for a Gasketing or Sealing Part

Comments Off on Selecting the Most Cost-Effective Material for a Gasketing or Sealing PartSelecting an Elastomer or other non-metallic gasketing or sealing material for a project build is often the last consideration made in product design. Sometimes, there are existing drawings that can be used as a template for the requirement. However, the wrong material selection can result in a costly delay. In this article, we’ll guide you through the process to help you find the right option for your specific application.

Understanding Sealing or Gasketing Requirements

It’s important to gather as much information as possible about your sealing or gasketing material needs, and if possible, create the dimensional drawing before reaching out to your purchasing team and suppliers in a rush. You can start this process by asking, and answering (or getting answers to) some basic questions:

- What is the purpose/function of the part?

- Will the part see excessive heat or cold? What are the min/max and continuous operating temperature requirements?

- Does the part need to be resistant or conductive to electricity?

- How do factors like hardness (durometer), density, specific gravity, etc., tie into performance?

- Are there additional requirements relating to compression deflection and compression set?

- Does the part need to have extra abrasion resistance or tensile tear properties?

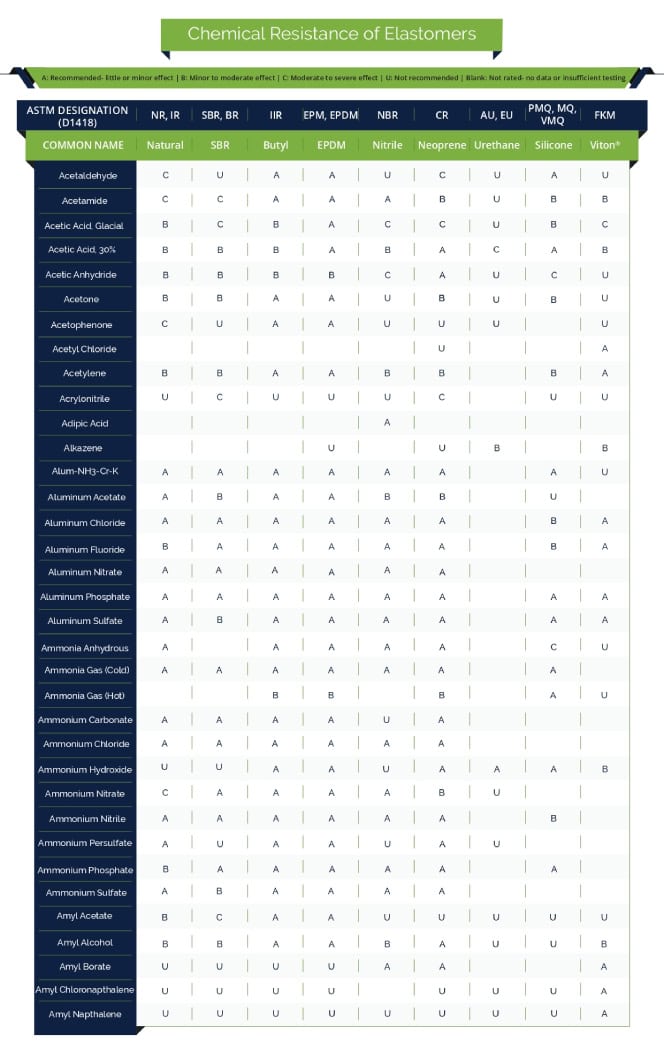

- Will the part be exposed to sunlight, UV, ozone, or chemicals, including oils and cleaning agents? What are the known environmental concerns?

- What are the material certification requirements (i.e., UL, NSF, NFPA, MVSS)?

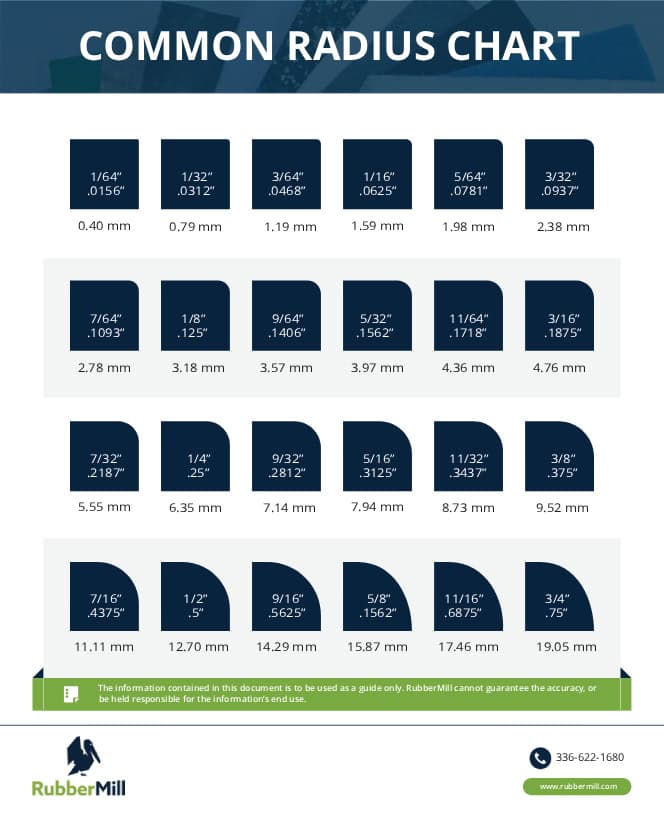

- What are the dimensional tolerance requirements?

- What is the desired order quantity and estimated annual usage?

- Are there any special requests regarding color, special labeling, or packaging?

Using this information, start a dialog with your materials and purchasing team members and suppliers to make the appropriate material selection, finalize the engineered drawing, and initiate an RFQ to move the project forward.

Choosing the Right Material

Elastomers are generally mixed and milled from raw materials, including base compounds, lubricants, fillers, and additives, to achieve desired or required physical properties. The more complicated and less common the mix, the higher the associated cost. Utilizing a common, readily available compound (that meets the physical requirements) is the most cost-effective and least challenging path to a healthy supply chain.

The use and notation on engineered drawings of ASTM callouts (D2000 for solid elastomers and ASTM D-1056 for flexible cellular materials) can be very helpful. Ask the vendor to quote their material of choice that meets the requirements and provide supporting documentation (data sheet or similar) for review with the quotation.

Base polymers and additives, and mixed (milled) compounds do impact part price but should not determine the final material selection. Different compound recipes are available in a range of prices depending on the quality required. SBR is typically the most cost-effective compound. EPDM, Natural Rubber, Neoprene, and Nitrile are competitively priced and a little more expensive for common recipes. Silicones and Urethanes will generally cost more, as will designer compounds like Viton.

Opting for the Right Tolerance Schedule

Preformatted drawing templates include dimensional tolerance schedules that are often too tight for elastomeric products. When using these formats, be sure to add notes for tolerances based on RMA (Rubber Manufacturers Association) published tolerance schedules. For most solid and sponge rubber parts, the “Commercial Tolerances Schedule” will work. [link to RMI technical data]. If you have critical dimensions that need to be tighter than the commercial tolerance for the selected manufacturing technique, be sure to note this in the drawing for that specific measurement or consider using the next higher Class tolerance schedule.

Keep in mind that requiring higher precision tolerances can be costly in tool design and tool life. Finally, be prepared to work with your vendor to expand problematic tolerance requirements through the sampling process when it does not impact performance. For many gaskets and basic molded rubber parts, “Fit and Function” is all that is needed.

Choosing the Right Manufacturing Method

Quantity requirements are very important for selecting the proper manufacturing technique and establishing an appropriate price point. For molded parts, deciding the mold size (number of cavities) and design will impact part price. For lower quantities (hundreds and thousands), the material cost will be a smaller piece of the part cost. With larger volumes (hundreds of thousands and millions), a larger tool can lower part price and material costs.

Quantity information is also important for parts made from sheets or rolls of material. The cutting method, tool size, available equipment, and number of fabrication steps are determined by suppliers based on the number of parts needed to support production.

Compression Molding vs. Injection Molding

Compression Molding is suitable for most common three-dimensional molded rubber parts, like grommets or stoppers. It is a cost-effective moderate- to high-volume production method for rubbers with good flow characteristics. Injection molding is used for more complex shapes and tighter tolerance requirements. These tools are more expensive than compression mold tools. Extrusion tools, on the other hand, are relatively inexpensive. Profile seals, rail bumpers, and ID/OD cut-to-length spacers and washers with high volume requirements are all very cost-effective options.

Utilizing 3D Printing Technology

3D printing can shorten development times by prototyping and avoiding unforeseen problems for three-dimensional mold parts. This technology is constantly improving to allow the printing of soft thermoplastics and other materials. Printed parts will likely not have all of the physical characteristics of the finished part that you will need but are great for making sure that the design is correct before building hard tooling.

Dieless vs. Die Cut Presses

Fabricated parts cut from flat sheet also rely on accurate quantity requirement information. Improved technology offers low-volume dieless cutting using AutoCAD setup fees and no tooling. Other advantages include prototyping and minor dimensional changes at lower costs for custom modifications or part revisions.

Die cut presses are more focused on larger volume requirements made from rolls or sheets, as you are able to utilize large dies with multiple cavities. Nesting and kitting can be achieved with both methods if properly planned to minimize labor and material costs.

Slitting Methods

Roll slitting and log slitting are very cost-effective for making large volumes of peel-and-stick materials at the same thickness and width.

Contact RubberMill to Learn More

Making a quality part begins with selecting the right material. Selecting the right material begins by doing a little research, answering a few questions, and getting help from your purchasing team to identify the preferred supplier options and secure quotes for tooling, set-up samples, and parts. We hope that you will allow RubberMill to be a part of this process.

Contact us today or request a quote to get started.