Common Elastomer Properties

Comments Off on Common Elastomer PropertiesWhat Are Elastomers?

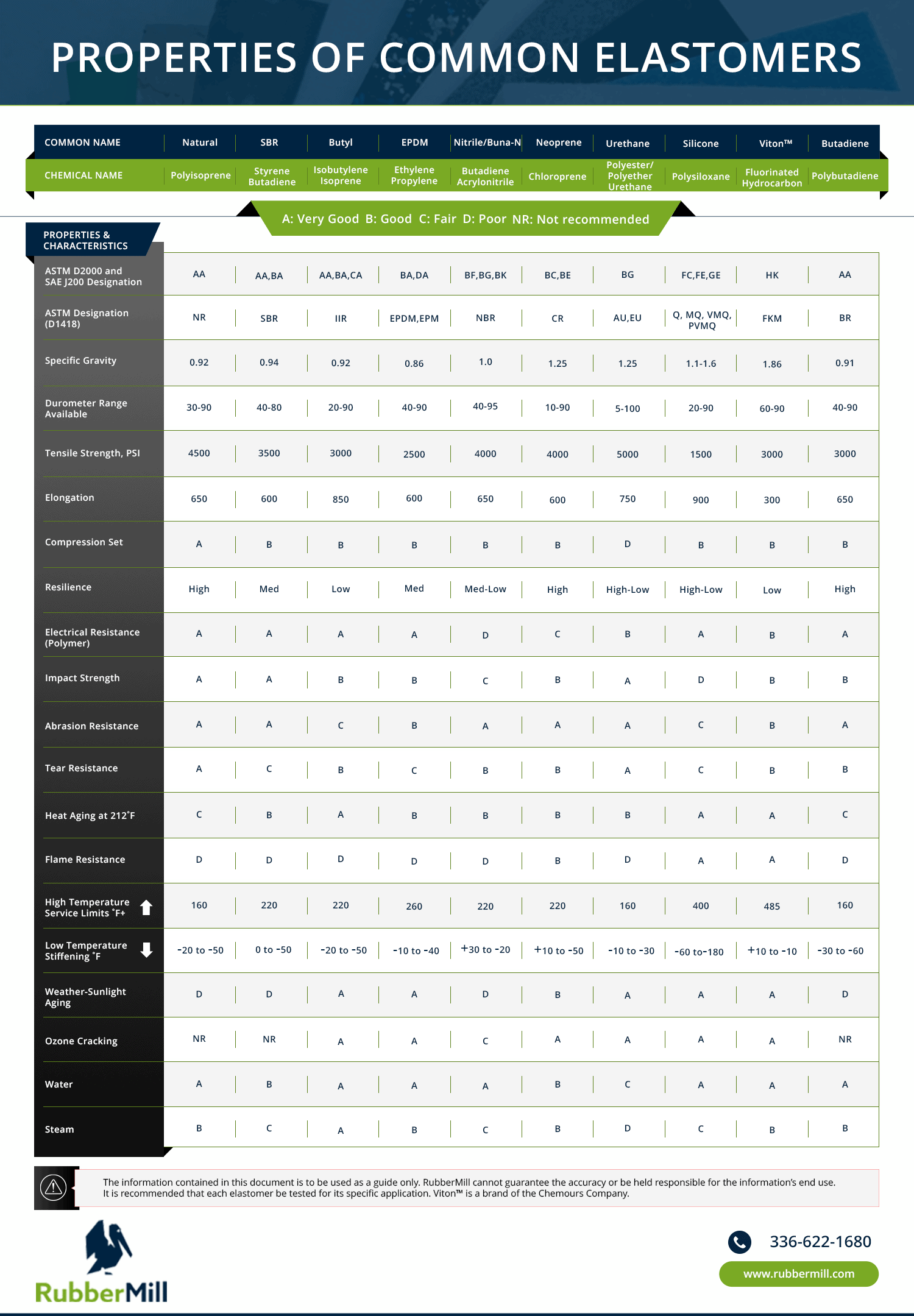

Elastomers are synthetic or natural materials capable of repeated stretching without losing their original shape. Natural rubber is one of the most widely known elastomers. Choosing the best elastomeric material for your industrial needs requires understanding the different types of elastomers on the market. Below are common elastomers and how they fall into various categories, with some overlap based on their appropriate applications.

These general-purpose elastomers are some of the most common in use today:

- Neoprene

- Natural Rubber

- SBR

- Silicone Rubber

Examples of high-temperature elastomers include:

- Neoprene

- Viton®

- Silicone Rubber

- EPDM

Low-temperature elastomers include:

- Silicone Rubber

- Butadiene

- Butyl

- Natural Rubber

High-performance engineered elastomers, such as neoprene and butadiene, have a higher price point and offer greater durability in harsh operating environments. These oil- and hydrocarbon-resistant elastomers are also essential, such as for pressurized seals in chemical manufacturing.

Because the properties of many elastomeric materials have significant overlap, choosing exactly the right elastomer for your application requires working with a specialist in elastomer applications.

Common Elastomer Properties

An elastomer’s properties are the combined result of several performance factors.

Specific Gravity

Specific gravity refers to the elastomer’s density compared to water. This property provides several indications of the elastomer’s strength, weight, and the media it can contain. Knowing the material’s specific gravity helps manufacturers evaluate the product’s ability to withstand heavier loads without becoming brittle, its wear resistance over time, and the rate at which it absorbs solvents and oils.

Most elastomers have a specific gravity between 0.9 and 2.0. Viton®, urethane, and neoprene have the highest specific gravity out of all rubber materials at 1.86, 1.25, and 1.25.

Durometer Range

The durometer rating provides a relative comparison of hardness for materials. For example, most rubber materials are measured by either the Shore A or Shore D durometer scales. Shore A durometer ratings cover soft materials to certain semi-rigid and inflexible plastics. Shore durometers measure harder materials, including semi-rigid plastics and hard rubbers and plastics.

Silicone rubber has one of the lowest durometer ratings (Shore A 20-30) of any elastomer, making it suitable for cushioning or molds. Nitrile has a higher durometer rating (Shore A 60-70), which makes it effective for high-pressure seals and gaskets.

Strength

There are several measures of elastomeric strength. It’s important to know what type of strength your elastomer application requires.

- Tensile Strength measures the elastomer’s breaking point.

- Elongation at Break indicates how much the elastomer will deform before it reaches the breaking point. A higher elongation at break value normally comes at the expense of lower tensile strength.

- Tear Resistance denotes the level of force required to tear the material.

- Impact Strength measures how well an elastomer resists sudden impacts and shock loads. Other variables, like the elastomer’s temperature and thickness, can affect its impact strength. Elastomers with the highest impact strength include natural rubber, SBR, and urethanes.

- Abrasion Resistance shows how well the elastomer resists scraping, rubbing, erosion, and other mechanical forces. Examples of elastomers with exceptional abrasion resistance include polyurethane, nitrile, and SBR.

- Compression Set Resilience is a measure of an elastomer’s height loss or deformation after withstanding a compressive force for some time. It also relates to how well the elastomer returns to its original shape. Seals, gaskets, and O-rings face continual compression, so they require elastomers with the best compression set resilience. Natural rubber generally has a very high compression set resilience, although this depends on the formulation.

Temperature Resistance

Elastomers also deteriorate under excessive heat. Heat aging and other temperature resistance tests can simulate the elastomer’s behavior under extreme temperatures and help establish its expected service life under particular conditions. Viton® and silicone rubber have the best flame resistance and highest operating temperatures, up to 400-485 °F.

Low temperatures render elastomers brittle and stiff, and rubber crystallization is a risk mostly for non-vulcanized rubber. Silicone rubber has the best low-temperature resistance, as low as -180 °F.

Elemental Resistance

This property refers to an elastomer’s resistance to outdoor elements. These tests (and associated standards) help determine the material’s elemental resistance:

- Dielectric Strength – ASTM (D-149)

- Heat Aging – ASTM (D-573)

- Ozone – ASTM (D-395)

- Water – ASTM (D-1149, D-1171)

Premium Elastomers From RubberMill

With more than 30 years of experience in the industry, RubberMill provides OEMs across diverse industries with the high-quality nonmetallic parts they need. Our technical, engineering, and sales teams work together to help customers determine which elastomers will best meet their goals. We consider every design factor, delivering reliable custom gaskets, insulation, and acoustic and vibration control solutions.

To learn more about which types of elastomers are most suitable for your specific product or application, contact us or request a quote today.

ASTM Testing Methods for Elastomers

Comments Off on ASTM Testing Methods for ElastomersAmerican Society for Testing and Materials (ASTM) is a global organization with thousands of members who are technical experts in different fields. They work to develop and publish comprehensive standards, consisting of test methods, specifications, classifications, guides, and best practices for different materials, products, and systems used in many industries.

Ensuring the elastomers used in your products meet ASTM standards is a major step toward meeting product performance and safety requirements, quality expectations, and longevity.

To aid in the classification of materials and products, all ASTM documentation uses a system of letters. The letters A through G designate broad material categories. Most elastomers are grouped under ASTM D, “miscellaneous materials and products.”

In this article, we’ll focus on some of the many common ASTM testing standards for elastomer materials.

Common Elastomer ASTM Test Methods

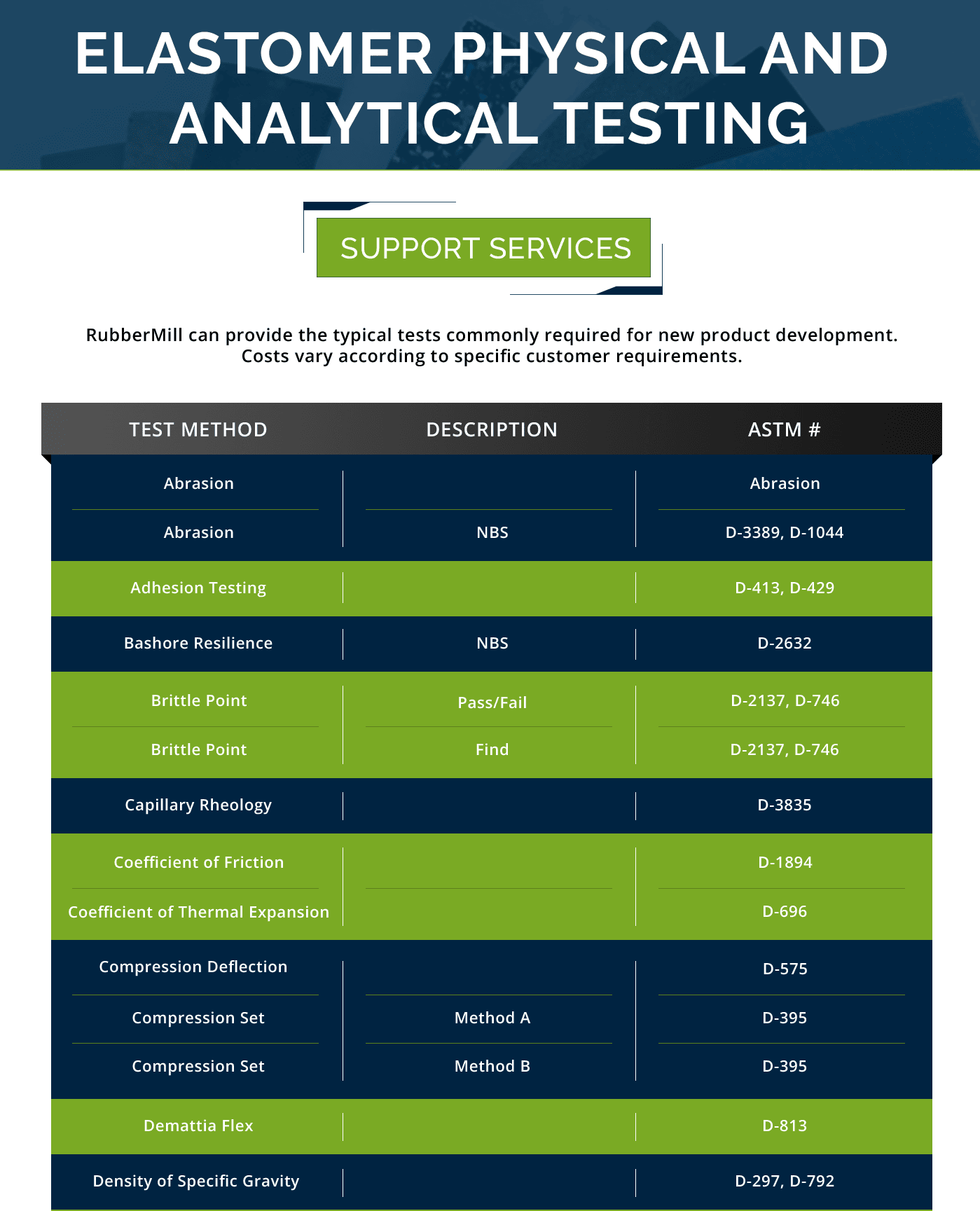

ASTM test standards describe why and how to conduct specific tests on materials or processes. The standards explain the scope of the test, what it measures or observes, specifications for equipment used in testing, specimen requirements, and procedures for the test.

Generally, the tests listed below allow manufacturers to measure and observe the properties, behaviors, changes, and limitations of different types of vulcanized thermoset rubbers and thermoplastic elastomers. To obtain accurate results, all tests must be performed under controlled conditions with specialized and properly calibrated machinery.

Some of the most common tests for elastomers include, but are not limited to:

- ASTM D412 (Tensile/Elongation). This is a test of the material’s ability to withstand tensile forces. Tensile properties including tensile strength, tensile stress at a given elongation, ultimate elongation (the point of rupture), and tensile set or residual deformation are measured before and after applying force. This test is conducted using a universal testing machine, also referred to as a tensile testing machine or pull tester.

- ASTM D624 (Tear Resistance). This test measures resistance to tears by finding the force per unit thickness required for the specimen to rupture or tear. Typically, any materials that are tested to D624 also undergo ASTM D412 testing to measure tensile strength and elongation.

- ASTM D395 (Compression Set). This test observes the material’s compression set, or its ability to retain elasticity after prolonged exposure to compressive stress. The test can be performed with a static force applied to the material or a rapid repeated deformation and recovery. This test is particularly applicable to elastomers used in seals, vibration dampers, and machinery mountings.

- ASTM D2240 (Durometer). This is a method for measuring the durometer hardness of rubber materials. The material is compared to 12 established, universal reference scales called shore hardness scales (Types A, B, C, D, DO, E, M, O, OO, OOO, OOO-S, and R). The test is performed by measuring the depth of an indentation made in the specimen under controlled conditions.

- ASTM D573 (Heat Resistance). This test assesses physical and chemical changes to the material when exposed to heat. Elastomers must be able to resist deterioration of physical properties caused by thermal and oxidative aging. This testing procedure offers a way to assess certain performance characteristics of rubber under the specified accelerated conditions. Properties are measured before and after exposure.

- ASTM D1171 (Ozone Resistance). This is a test to determine molded or extruded rubber products’ resistance to ozone cracking and outdoor weathering. The test does not apply to hard rubber materials but can be adapted to extruded or molded soft rubber materials, as well as sponge rubber used for automotive applications (i.e. window weatherstripping).

- ASTM D471 (Fluid Resistance). Elastomers used for gaskets, seals, diaphragms, sleeves, and hoses are often exposed to fuels, greases, oils, and other fluids during operation. This test assesses a material’s ability to withstand the effects of these liquids by simulating operating conditions via controlled accelerated testing.

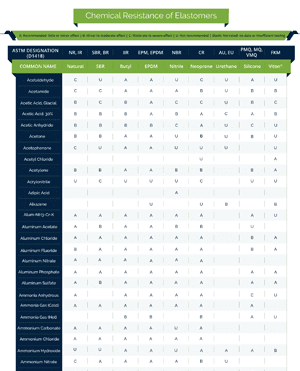

- ASTM D297 (Chemical Analysis of Rubber). This is a group of quantitative and qualitative tests used to analyze the composition of natural and synthetic crude rubbers. The methods are divided into general and specific testing categories. Part A tests look at the type and amount of major constituent compounds, while part B tests determine the specific polymers present.

Related Resources

At RubberMill, we provide testing services for several of the ASTM tests commonly required for new product development.

View our elastomer physical and analytical testing chart here.

A chart of chemical resistance information for nine common elastomers is available here.

Elastomer Products by RubberMill

RubberMill is an ISO 9001:2015 certified non-metallic component manufacturer with over 30 years of experience. We are a trusted resource for ASTM testing as well as materials for custom die cutting, lamination, and more. A variety of die cut and molded parts are also available in stock.

Please contact us or request a quote to learn more about our capabilities or to talk with an expert about your next project.