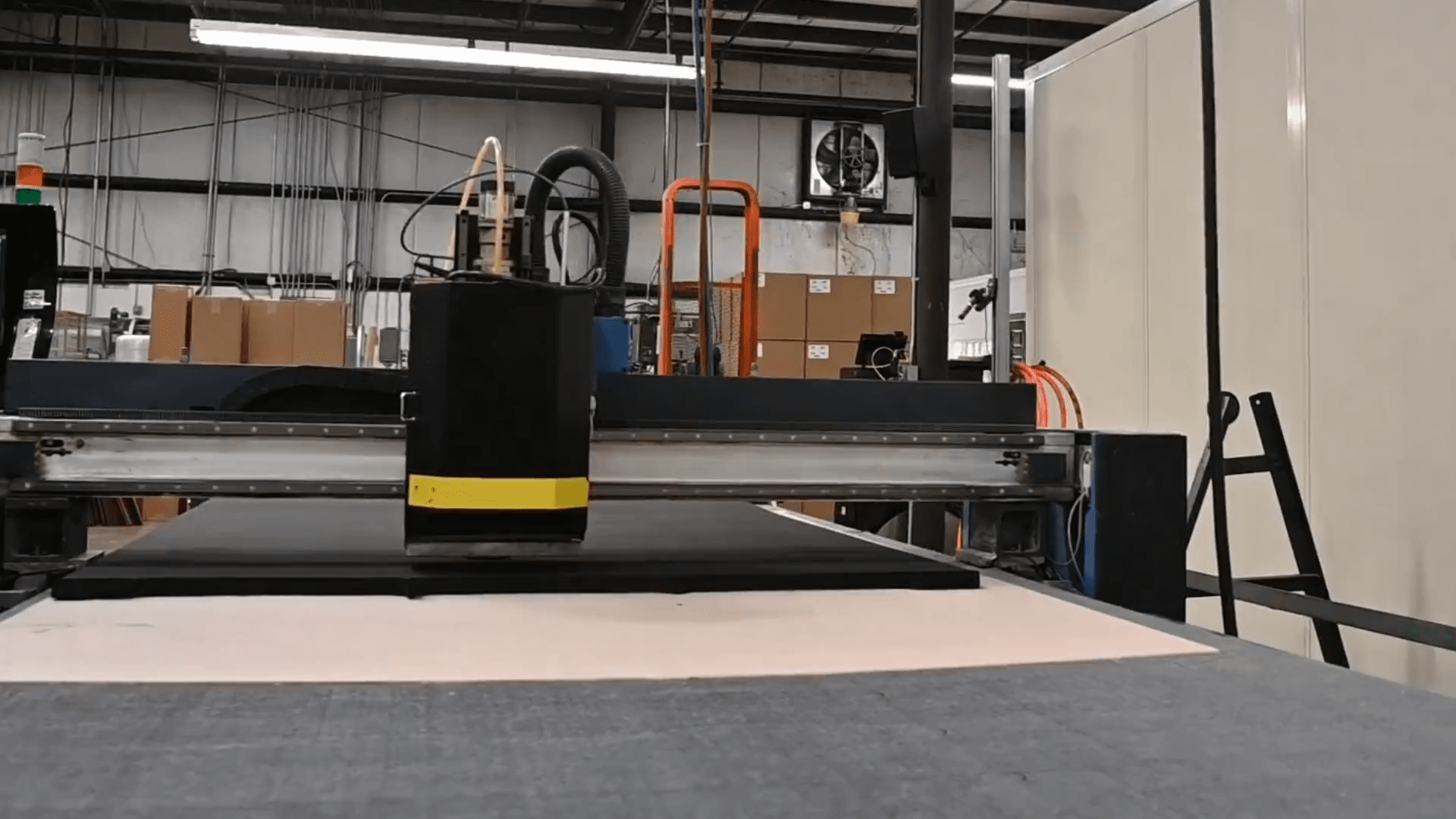

RubberMill has a range of in-house manufacturing capabilities available, including die cutting, kiss cutting, slitting, and more. This enables us to respond quickly and provide manufacturers with custom parts, at a volume and price that meets their unique needs.

RubberMill has a range of in-house manufacturing capabilities available, including die cutting, kiss cutting, slitting, and more. This enables us to respond quickly and provide manufacturers with custom parts, at a volume and price that meets their unique needs.

We have the ability to perform a wide variety of cutting methods on all kinds of metallic & flexible materials – view our material list here.