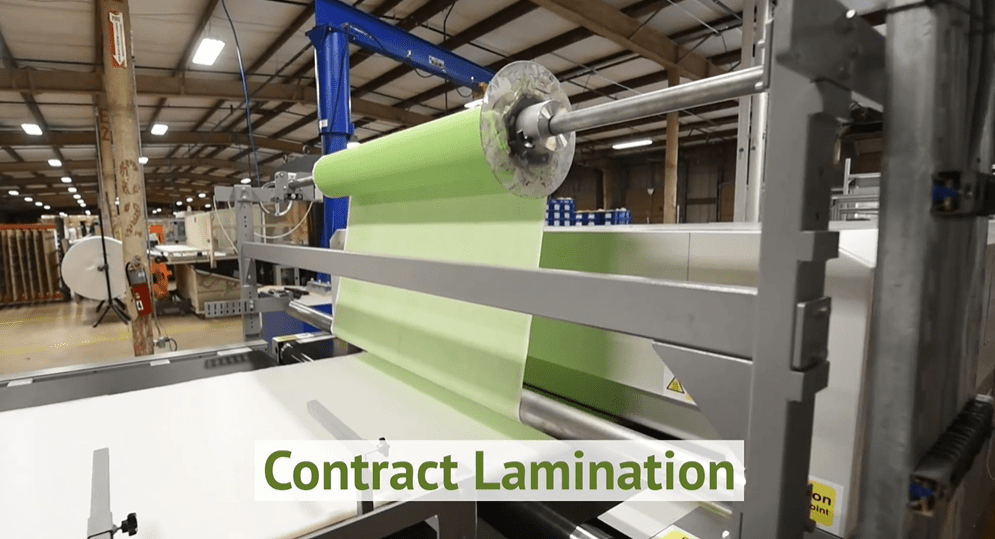

At RubberMill, we offer quality contract lamination services as part of our double belt press laminating capabilities. We utilize methods such as consolidating, belt laminating, simple roll application of water-based adhesives, and hot melt permanent and pressure-sensitive beads and sprays. In addition to these capabilities, we also offer pressure-sensitive adhesive (PSA) application as a value-added service.

Flatbed Lamination

Our advanced Pressurized Flatbed Laminating technology utilizes zoned heating, cooling, and pressure to form unique fabric, foam, nonwoven, and film constructions based on customer specifications and requirements. We can delicately laminate high loft materials with a facing or reduce them to high-density pre-preg composites. At RubberMill, our double belt press lamination capabilities include:

- Different material combinations are utilized in contract lamination

- Utilization of adhesive webs and films

- Densify materials – combine various substrates

- Widths of up to 70 inches

Our Reliant Laminator

With our contract lamination services, we use a state-of-the-art belt press lamination machine to meet our customers’ needs. Benefits of this machine include:

- Horizontal flat conveyor run. This machine features a horizontal flat conveyor run, allowing it to feed rigid and flexible materials through the process stress-free.

- Compatible with various widths and thicknesses. Our belt press lamination machine can handle materials of only a few microns thick all the way up to 150mm thick with widths up to 1800mm.

- Customized pressure. The top and bottom conveyors can feed materials with high pressure or without pressure. The machine can also apply pressure during the heating and cooling process to allow products to be compressed and calibrated. Additionally, the calendering nip roller system can independently apply additional high pressure in one or more areas of the tunnel.

- Efficient. Our belt press lamination machine can laminate multi-layer processing in a single pass.

- Optimal control. The zoned heating controls allow lengthways, width, top, and bottom heating to be independently controlled.

- Integrated inspection system. The integrated inspection system ensures optimal quality control.

- Slitting and crosscutting. Our machine is also capable of slitting and crosscutting, enabling us to provide materials in both sheets and rolls.

Applications for OEM Contract Lamination

At RubberMill, we can serve a wide range of industries and applications with our contract lamination services, including:

- Acoustic insulation

- Automotive

- Appliances

- Construction

- Thermal insulation

Benefits of Contract Lamination

Outsourcing your lamination processes offers a quick and easy way for businesses to save time and money in the manufacturing process.

Reduced Costs

Outsourcing laminating services eliminates costs associated with additional manpower and machinery. Lamination equipment can be very expensive, so by not having to purchase it, you can save a lot of money. Using outside laminating services also prevents you from having to hire skilled professionals or train current employees. With contract lamination, you only pay for the products and services you need when you require them.

Save Time

Our contract lamination process involves experts at every step of the process. As such, we can quickly identify issues and determine the appropriate solutions. This ensures a quick and efficient manufacturing process for faster time to market.

Adhesive Lamination Capabilities

At RubberMill, we also offer PSA application as a value-added service. Our PSA systems are designed to meet various industrial requirements. Depending on your needs, we can apply rubber and acrylic-based PSA transfer systems to most fiber, sponge, and rubber materials. In addition, we can laminate roll goods of up to 60″ wide on one or two sides to form layered composites.

Rubber-base PSA Characteristics

- Cost-effective

- Adheres to a broad substrate variety

- Poor UV resistance

- Medium service temperature (up to 200°F)

- Good initial tack and adhesion

- Low resistance to solvents and plasticizers

Acrylic-base PSA Characteristics

- Good aging performance

- Poor to medium initial tack

- High service temperature (up to 300°F)

- Impressive resistance to plasticizers and solvents

- Excellent UV resistance

- Medium cost

Important Tips for Use of Parts with PSA

- Storage: Keep all enclosed parts in a cool, dry place (64 °F-76 °F) with 50-75% humidity. Suppliers aren’t liable for the performance of parts stored longer than six months or stored improperly.

- Surface Preparation: Ensure the surface is clean and free from oil, grease, moisture, dirt, dust, and cutting fluids. Different surfaces tend to lead to different bond strengths. As such, also ensure you don’t use cleaning agents that leave residues.

- Application: Before applying, ensure that both parts are at room temperature (72 °F). Apply the parts firmly and uniformly. If the part is stretched during application, it will release from the surface.

OEM Contract Lamination Services

RubberMill is an industry leader in providing top-of-the-line contract lamination and adhesive lamination services. Our products and services are designed to ensure maximum customer satisfaction. Contact us to learn more or request a quote from our OEM contract lamination experts.